Scan and pay attention to us

Dassault Platinum Partners

Dassault Certified Partners in Education

Case

Aerospace Ships and marine engineering Industrial equipment High-tech Energy Transportation Architecture400-900-7701

Online Customer Service Hotline

Dassault is the first C&SI Consulting & Systems Integrator consultant and system Integrator

Copyright 2018 Shanghai ATOZ Information Technology Ltd. 沪ICP备08114470号-1

Zhejiang Wanxiang Precision Co., Ltd

Customer introduction

Founded in 1988, Zhejiang Wanxiang Precision Co., Ltd. is a professional auto parts company with a high-tech, high-end market and high-precision auto parts products. It mainly develops and produces "WGC", "Wanxiang WANXIANG" brand automobile wheel hub bearing unit (first generation, second generation, third generation with ABS electronic speed sensor), automobile wheel bearing and other automotive bearings, automobile anti-lock braking system (ABS), automotive electronic hand brakes (EPB) and other automotive electronics.

Project Objectives

In the process of R&D and design, the diversification of products has caused Wanxiang Seiko to have certain problems in the solutions of the corresponding OEMs. Through CATIA 3D design, rapid knowledge reuse can be realized; professional CAE analysis can solve the problem of relying too much on sample experiment; finally realize the overall development cycle and achieve the response to the requirements of the OEM.

solution

Contact analysis

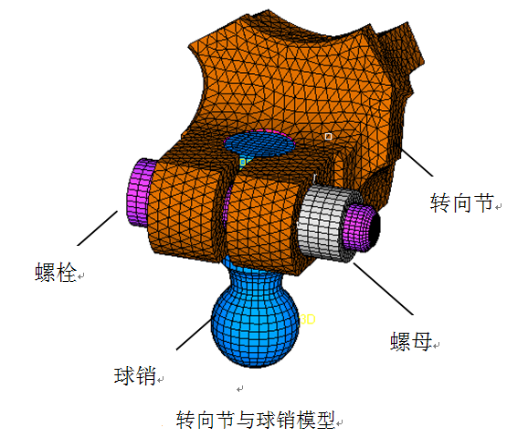

The contact analysis here takes the contact analysis of the suspension structure of a domestic model as an example. From the perspective of different suspension structures, the load transmitted from the knuckle to the lower control arm is generally relatively large, and the reliability of the connection here directly affects the safety of the vehicle. The knuckle and the lower control arm are mainly connected by a ball pin, and the ball pin is fixed on the knuckle by the pre-tightening force provided by the pre-tightening bolt, and the force is relatively bad, so the contact between the knuckle and the ball pin is made. Stress analysis is of great significance.

The figure above shows the meshing result of the model. The entire assembly consists of four parts.

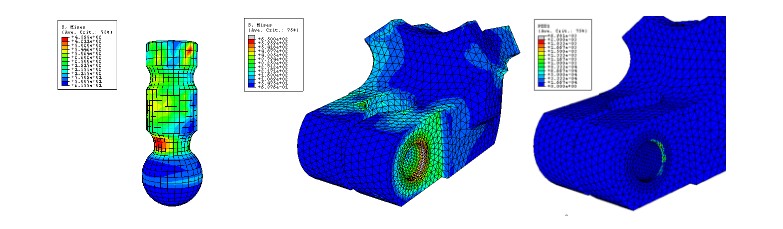

The above figure shows the respective Mises stress distribution when the ball pin and the steering knuckle contact

It can be seen that Abaqus/Standard has powerful nonlinear analysis function and has good convergence for contact analysis. Through the software, complex contact problems such as knuckle ball pin can be well analyzed, the stress distribution is reasonable, and the stress value is more authentic.

In addition, we also use the professional analysis software simulia to provide the following solutions for analysis:

1) rigid strength analysis

2) Rubber wear analysis

3) Mechanical processing analysis

4) Topology optimization analysis

5) Fatigue analysis. Radiated noise analysis

6) Collision analysis

User revenue

1) Reduce physical prototype testing and reduce costs

2) Accelerate the research and development rate and shorten the time-to-market for new products;