Scan and pay attention to us

Dassault Platinum Partners

Dassault Certified Partners in Education

Case

Aerospace Ships and marine engineering Industrial equipment High-tech Energy Transportation Architecture400-900-7701

Online Customer Service Hotline

Dassault is the first C&SI Consulting & Systems Integrator consultant and system Integrator

Copyright 2018 Shanghai ATOZ Information Technology Ltd. 沪ICP备08114470号-1

Aviation industry composite tail design and performance analysis system

Background of the project

Composite material technology is one of the four major structural materials technologies of aircraft. Its proportion of the aircraft is one of the advanced performance indicators of aircraft. Its specific strength, high specific stiffness and layability can be tailored to the aircraft structure. More and more widely. For more than half a century since the birth of composite technology, how to effectively design composite structures to reduce structural weight has always been an innovative source of aircraft structural design. The increasing weight, cost, and use environment have increased the structure of composite materials. Design difficulty.

One of the most difficult and time-consuming aspects of composite structural design lies in the layup design of composite structures. Due to the lack of effective optimization design methods, traditionally, through hand layup to carry out the layer design, the designer needs There is a wealth of experience in composite structural design to be able to do the job. For large composite structures with multiple thickness zones, it is extremely cumbersome and time consuming to manually coordinate the material in each thickness zone, and this work is often Because of the factors such as weight reduction, insufficient local bearing capacity, and poor processability, multiple rounds of cycles are required, which increases the design cycle of composite structural members. On the other hand, due to the lesser summary of composite structural design, a large number of paving design experiences are scattered in the design drawings and design reports of each component, which is not easy to manage. In the prototype design phase, each model lacks a reference basis for the layup design and requires effort to redesign/calculate the initial layup.

In recent years, the requirements for weight reduction of aircraft structures have become more prominent. By increasing the proportion of composite structures in aircraft structures and optimizing the layup of composite structures, it is one of the main means of weight reduction of aircraft structure design, and current aircraft. The cycle of structural design is getting shorter and shorter, and the management requirements for composite structural ply design and the need for ply optimization design become more and more important.

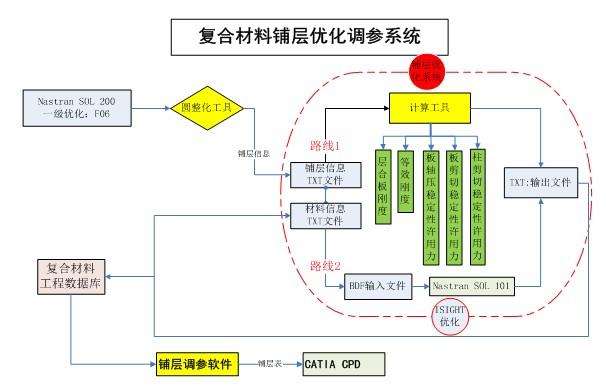

To this end, an effective composite layer management/optimization design tool was developed and combined with the development of Isight to form a complete set of composite structure structure management - structure optimization - layer optimization - part design digital design method, It can greatly improve the level of composite structure design of a design institute, reduce the work pressure of designers, and effectively shorten the development cycle of various products.

system structure

Project benefit

Innovative

(1) For the knowledge and experience accumulated in the design process of composite materials, other methods of adding complex processability for stability optimization - optimization design

(2) Visualization of the parameter adjustment method to improve the efficiency of manual adjustment

2. Universality

ISIGHT is the optimized design process for curing

Optimized system developed for optimal design of laminate layup for laminates and rods

3. Simplicity

No need to understand ISIGHT's complex design methods and operations, simple operation, direct application system for stability optimization

4. Practicality

The system's engineering calculation algorithm, layering and rounding, packaged into independent software tools, can be used separately in the work